3D scan systems

Nowadays it is possible to find both fixed scanners (that is to say, to be permanently mounted) and portable ones available for sale: the most renowned one is GoScan 3D, that is a manual scanner that has be pointed towards the objects while revolving around them so to acquire the whole surface; it is supplied with a self-positioning system that compensates the errors due to the fact that the hand is not always stable and that, by rotating, the scanner’s height it changes. As for the scan it uses lasers and a video camera and it has a scan accuracy of 0.1 mm (the resolution is 0.2 mm).

Many scanners work just like GoScan 3D.

Another solution – and certainly a very affordable one – for carrying out 3D scans consists in using devices that are born for other purposes, such as Microsoft Kinect or equivalent ones (for example, Asus Xtion Pro) for modern gaming consoles, capable of detecting the player’s movements and of sending them to the system so that he may be able to command his own avatar in a videogame or to transmit the movements to an interactive program. Kinect works like this: the infrared projector projects a specific pattern, made of equidistant dots. By analyzing the image obtained by means of the IR video camera, Kinect determines the the distances among the various points, and from them it acquires the distance and the inclination of the lighted object. Since the IR beam starts from a restricted area and it gradually broadens as the distance increases (it is more or less conical…), where the dots prove to be very close among each other, it means that the object is close to the sensor; vice versa, if the distance among the dots is a remarkable one, it means that the object is farther away. In order to understand this better, imagine to place a polka dot blanket on a surface of an object: it is possible to identify the shape of the said item on the basis of how the dots are arranged, as the blanket gradually wraps the item itself. In order to acquire with Kinect and similar devices, you need a Personal Computer and the ReconstructMe software with the appropriate software for the sensor that has been used. A program that may be an alternative to ReconstructMe is Kscan3D, but in this case the Trial version does not allow to save the model, therefore it would not allow you to reach the printing stage (it is used only to evaluate its functions).

In order to carry out the scan via Kinect and similar devices the object must be placed before it on plate or a rotating stool, after that please place Kinect on a stable tripod.

In addition to these techniques, there is a laser and video camera scan (the lasers are two) of the rotating object, that is the subject of this article.

A technology that produces excellent results is – on the other hand – given by the fusion of stereoscopic and photometric data that, for example, is implemented on the Fuel3D Scanify scanner; there are still two lasers, but the video camera is a stereoscopic one and is calibrated on them. During the scan it supplies two kinds of data: 3D images and corresponding photometric features; the whole occurs in less than a tenth of a second. Afterwards, it processes the two pieces of data and compares them, so to have a very high accuracy. Such a system is ideal in order to acquire human faces, cloth weaves or natural elements such as flowers and plants.

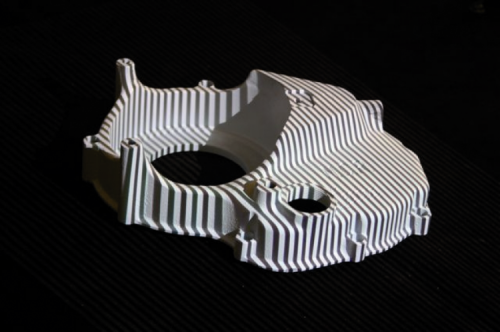

There is also the valued technique of the structured light scanning: a scan projects a known light diagram – typically having horizontal and vertical parallel lines – on the surface to be acquired. The deformation induced by the object’s surface is acquired by means of the video camera and it is taken advantage of, for the purpose of the calculation of the three-dimensional coordinates. Such systems are named full-field systems since for every sensitive dot of the acquisition system’s CCD or CMOS, three dots (x,y,z) in the space are acquired. Such a system allows the digitization of many dots at a time: according to the video camera’s resolution we may reach even different hundreds of thousands of dots.

By projecting a narrow light band on a three-dimension object a luminous line is obtained: from different observation points from the projector, it appears as distorted and it may be used for a correct geometric reconstruction of the lighted surface’s shape (luminous section). “Triangulation” is the name given to the procedure with which the shape of the object hit is reconstructed. A faster and more versatile method is the projection of luminous diagrams that consist in many lines at a single time, or of arbitrary luminous fringes. The light strips may be generated by means of interference of laser sources or via projection method. In the first case, two planar light sources are let to interfere between each other: the result is the creation of regular and equidistant lines. The size of the fringes may be modified by changing the angle between the two beams. This method allows to generate a very accurate pattern that has a great depth, but it is an expensive one, it suffers from reflection and from the typical flaws of the laser sources (speckles). The projection method takes advantage of means that generate incoherent light, that is to say the projectors; if on a side some small discontinuities are found in the scan (due to the pixel edges that compose the picture), on the other one they may be diminished by lens focusing. In both cases, the picture that is gradually created on the lighted surface is acquired by means of one or more video cameras.

Original Article published at Open Electronics

[tps_footer][/tps_footer]